Table of Contents

Features of the 2 Cylinder 4 Stroke Gasoline Engine Long Distance Remote Control Compact Cordless Forestry Mulcher

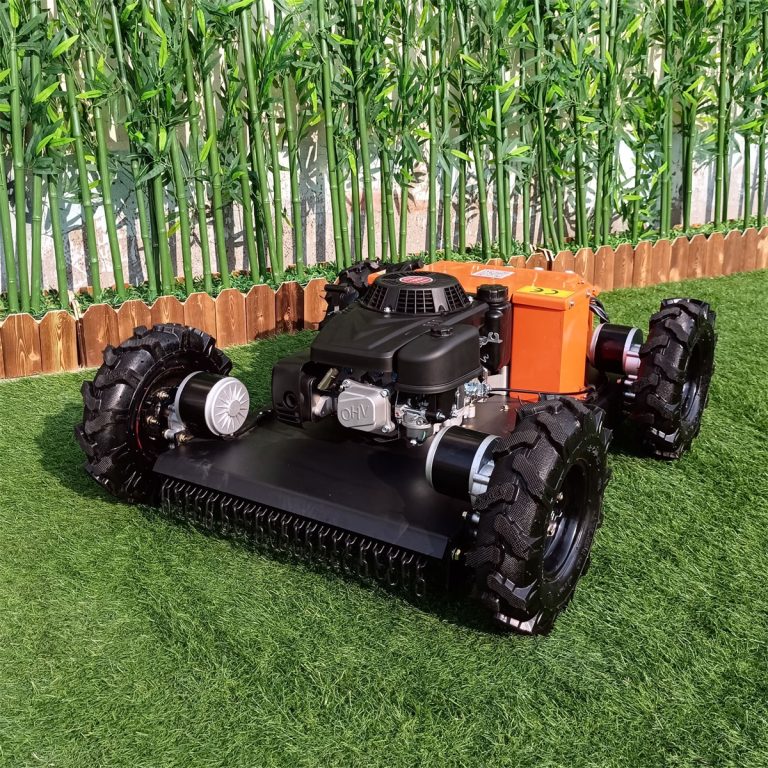

The 2 cylinder 4 stroke gasoline engine long distance remote control compact cordless forestry mulcher is powered by a high-performance V-type twin-cylinder gasoline engine. Specifically, it utilizes the Loncin brand, model LC2V80FD, which boasts a rated power of 18 kW at 3600 rpm. With a displacement of 764cc, this gasoline engine ensures strong performance and reliability, providing operators with the necessary power to tackle challenging forestry tasks. Equipped with a clutch that engages only when the engine reaches a predetermined rotation speed, this mulcher guarantees efficient operation while enhancing safety and control. The design minimizes wear and tear, allowing users to maximize the lifespan of the equipment. This feature makes it an ideal choice for those who require a machine capable of handling heavy-duty applications in various conditions.

Equipped with a clutch that engages only when the engine reaches a predetermined rotation speed, this mulcher guarantees efficient operation while enhancing safety and control. The design minimizes wear and tear, allowing users to maximize the lifespan of the equipment. This feature makes it an ideal choice for those who require a machine capable of handling heavy-duty applications in various conditions.

In addition to its powerful engine, this mulcher is equipped with advanced safety features. The built-in self-locking function ensures that the machine remains stationary until both power is applied and throttle input is engaged. This effectively prevents unintended movement, significantly increasing operational safety during use.

In addition to its powerful engine, this mulcher is equipped with advanced safety features. The built-in self-locking function ensures that the machine remains stationary until both power is applied and throttle input is engaged. This effectively prevents unintended movement, significantly increasing operational safety during use.

Versatility and Efficiency of the 2 Cylinder 4 Stroke Gasoline Engine Long Distance Remote Control Compact Cordless Forestry Mulcher

The 2 cylinder 4 stroke gasoline engine long distance remote control compact cordless forestry mulcher is not just about power; it offers versatility with its innovative design. The machine features electric hydraulic push rods, which enable remote height adjustment of attachments. This flexibility allows operators to adapt the mulcher for various tasks without needing to disassemble or reconfigure the unit manually. The intelligent servo controller further enhances the efficiency of the mulcher by precisely regulating motor speed. This smart technology synchronizes the left and right tracks, allowing the machine to travel in a straight line without constant adjustments from the operator. This reduces workload and minimizes risks associated with overcorrection, especially on steep slopes, making it an excellent choice for various terrains.

The intelligent servo controller further enhances the efficiency of the mulcher by precisely regulating motor speed. This smart technology synchronizes the left and right tracks, allowing the machine to travel in a straight line without constant adjustments from the operator. This reduces workload and minimizes risks associated with overcorrection, especially on steep slopes, making it an excellent choice for various terrains.